Lingerie Construction Part 4: Hems

'Rubans' cupped dress by Jean Paul Gaultier for La Perla. Photography by K. Laskowska

The fourth part of our lingerie construction series covers hems. You can read Part 1 covering types of stitches here, Part 2 covering stitch quality and linings here, and Part 3 covering seams here.

A hem is essentially the fabric edge on a garment or piece of fabric. It can be left raw or finished, with numerous finishing options. Certain finishings can be indicative of higher garment quality than others, but there are few hard and fast rules. It's just one of those things you have to learn through study and experience! Raw fabric edges can also be finished and enclosed within linings, as covered in Part 2.

Types of Hems

Roll hem

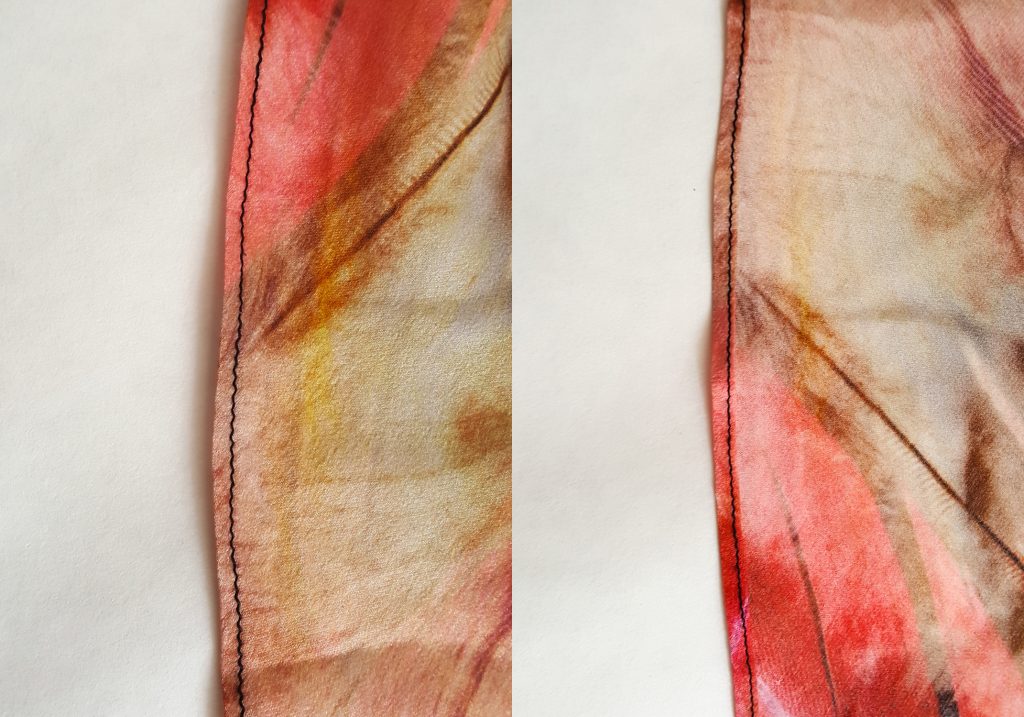

This Christine silk slip is finished with a lockstitched roll hem. The contrast black thread makes it a lot easier to see this finishing method. Photography by K. Laskowska

Roll hems are typically found in higher-end lingerie. The edge of the fabric is carefully rolled up to conceal the raw edge of the fabric and then lockstitched over. Lightweight fabrics, like chiffon and silk satin, can be especially challenging to sew with this technique, particularly if the fabric is cut on the bias (diagonal) or with a circle cut.

A similar external appearance can be achieved by overlocking the raw fabric edge and folding it to the interior of the garment, then lockstitching over. This is, however, a much cheaper method of finishing, as it requires significantly less time and skill to execute.

Babylock Hem

The leg edges on these Carine Gilson knickers are finished with a fine babylock stitch. This stitch is most effective on particularly fine fabrics like this lightweight silk. Photography by K. Laskowska

The raw edge of the fabric is finished with a babylock stitch, giving a fine, and usually fluted, appearance. A standard overlock stitch can also be used to finish a hem, but it doesn’t give a particularly attractive finish and is generally only found in lower-end lingerie.

Elasticated Hem

The underband of this Fleur of England bra is finished with a plush elastic trim, applied with a 3-point zigzag. This image shows both the interior and exterior of the bra. Photography by K. Laskowska

This is the type of hem you’ll find most commonly in garments like knickers, bras, and suspender belts. The raw edges of the fabric are folded and taped over or enclosed by an elastic tape (often with tension applied, especially when the fabric doesn’t have any of its own stretch). Then the hem is either zigzagged, three point or coverstitched over. This type of hem allows the garment to stretch and can give a more comfortable fit.

Trimmed Hem

The hem on this Chantal Thomass camisole is finished with a lace trim covering an overlock stitch. Photography by K. Laskowska

This type of hem uses a tape of some variety to either enclose or cover the exterior of the hem. The tape can be anything from a lace trim to a ribbon, and it can either fold the raw edge of the fabric underneath or simply be stitched over an existing hem.

Raw Hem

The hem on this tulle babydoll is simply cut and left raw. The twisted threads of the tulle mean that the fabric will be slower to fray than woven fibres. The decision to leave raw cut tulles is often a design decision, as it gives the garment a more diaphanous feeling, and a stitched hem would look clumsy. Babydoll by Jean Paul Gaultier for La Perla. Photography by K. Laskowska.

This type of hem leaves the fabric cut raw with no kind of stitch finishing. It is most appropriate in lightweight fabrics such as tulle, where a raw hem can give a very diaphanous appearance without major risk of fraying. Woven or knit fabrics can risk fraying or unravelling with a raw hem, and this kind of finishing would only be seen in budget garments. A scalloped lace or embroidered tulle does not need to be hemmed, as the scallop is already a ‘finished’ edge.

Synthetic fabrics can be specially cut and left with a 'sealed' edge, by using either special heated scissors or a laser. The heat causes the fibres to melt slightly, which seals the fabric and prevents any further fraying.

Bound Hem

Satin binding is used to finish the hem of these Nui Ami 'Paris' shorts. Photography by K. Laskowska

The raw edges of the hem are encased within a bias-cut fabric tape, which is specially folded to encase its own raw edges. Seams can also be finished with a binding, though this is less common.

Bonded Hem

This is one of the more high-tech options for finishing a hem, and tends to be used by brands with access to large scale manufacturing. It is usually reserved for synthetic fibres that have been heat sealed to prevent further fraying, with the fabric edge folded and glued down.

I hope this guide - and the entire series - helps you recognize different lingerie construction techniques. Have you learned anything you didn't know before?